Ensure Quality in Every

Supplier Delivery

Modules

-

Setup workflows, Inspections based on process, compliance, users and business rules.

-

Enterprise can configure existing quality inspection process and copy existing workflows, compliance standards and users for easy management.

-

Build product specs instantly using AI.

-

Clone and tweak existing documents effortlessly.

-

Set custom approval flows with ease.

-

Instantly publish latest versions to all users.

-

Auto-manage version history.

-

Assign specs directly to inspectors.

-

Create product-wise checklist instantly using AI.

-

Edit and reuse existing formats.

-

Configure multi-level approvals.

-

Auto-publish updated checklists.

-

Track versions without manual effort.

-

Assign checklists to inspections instantly.

-

Mobile-friendly checklist view auto-enabled.

-

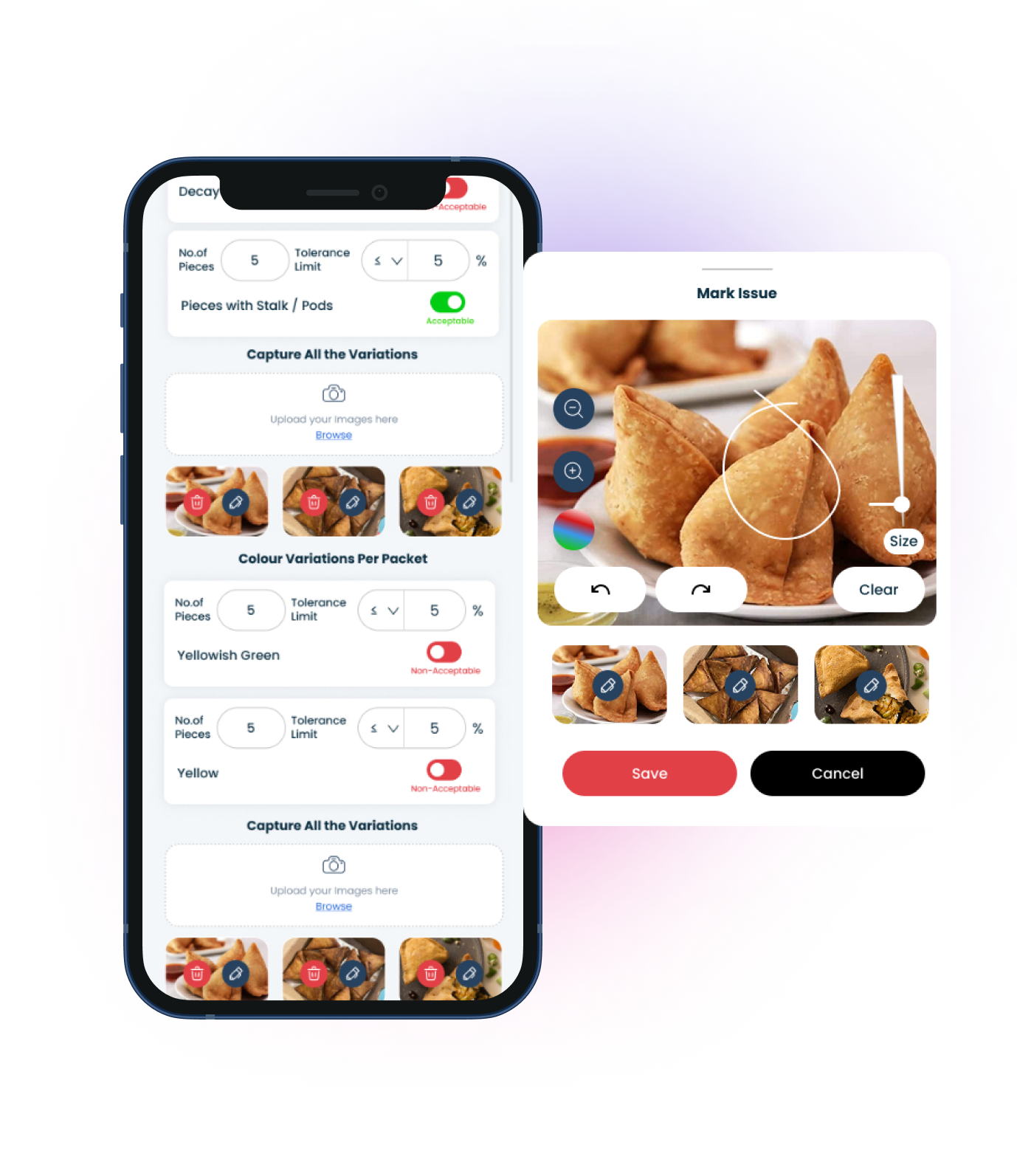

Tap-through to complete checklists on-site.

-

Upload multiple images with each entry.

-

Highlight issues directly on images.

-

One-tap submission for approval.

-

Auto-signature and timestamp included.

-

Add batch info to every inspection.

-

Work offline, sync when connected.

-

Download print-ready checklist reports.

-

Add container details to inspections.

-

Capture batch data with each dispatch.

-

Auto-calculate product counts by packaging.

-

Upload dispatch photos in bulk.

-

Create dispatch-specific templates.

-

Reuse and edit past checklists.

-

Set custom approval routes.

-

Push latest versions live in one click.

-

Version control done for you.

-

Assign to inspections instantly.

-

Fully mobile-optimized.

-

Tap to inspect and submit.

-

Signature + timestamp built-in.

-

Offline inspections, online sync.

-

Download printable dispatch reports.

-

Log container and batch info effortlessly.

-

Auto-calculate delivery quantities.

-

Attach multiple delivery images.

-

Use destination-specific checklist templates.

-

Copy, edit, and approve workflows.

-

Push updates across the team.

-

Manage versioning seamlessly.

-

Assign to delivery inspections instantly.

-

Mobile-friendly and easy to complete.

-

Submit with one tap.

-

Built-in signature and timestamp.

-

Offline inspection capability.

-

Export as PDF or print.

-

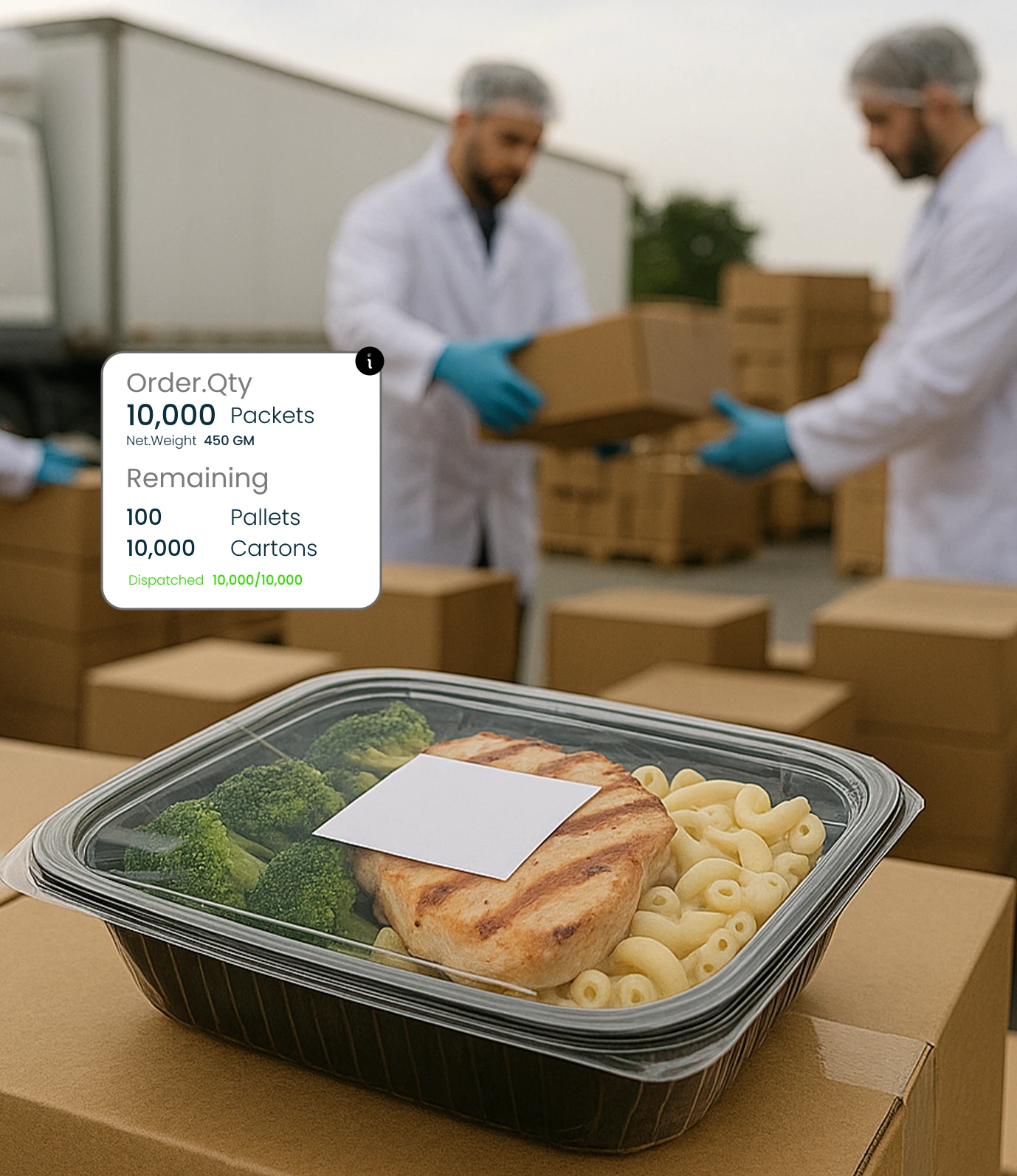

Auto-convert purchase orders to requisitions.

-

Assign product-wise purchase quantities.

-

Only allow approved supplier products.

-

Auto-generate packaging structures.

-

Plan production start/end dates.

-

Track overdue or delayed items.

-

Pause, resume, or end production at any point.

-

Monitor order vs. dispatch status.

-

Get visual insights with graphs.

-

Export full production reports.

-

Add and manage suppliers easily.

-

Group products by category.

-

Link specs and checklists to suppliers.

-

Activate or suspend supplier access.

-

Set up company structure.

-

Add branches and warehouses.

-

Configure destinations across countries.

-

Manage departments seamlessly.

-

Create users and custom roles.

-

Define approval flows by user type.

-

Restrict access with role-based controls.

-

Scale easily with unlimited users.

-

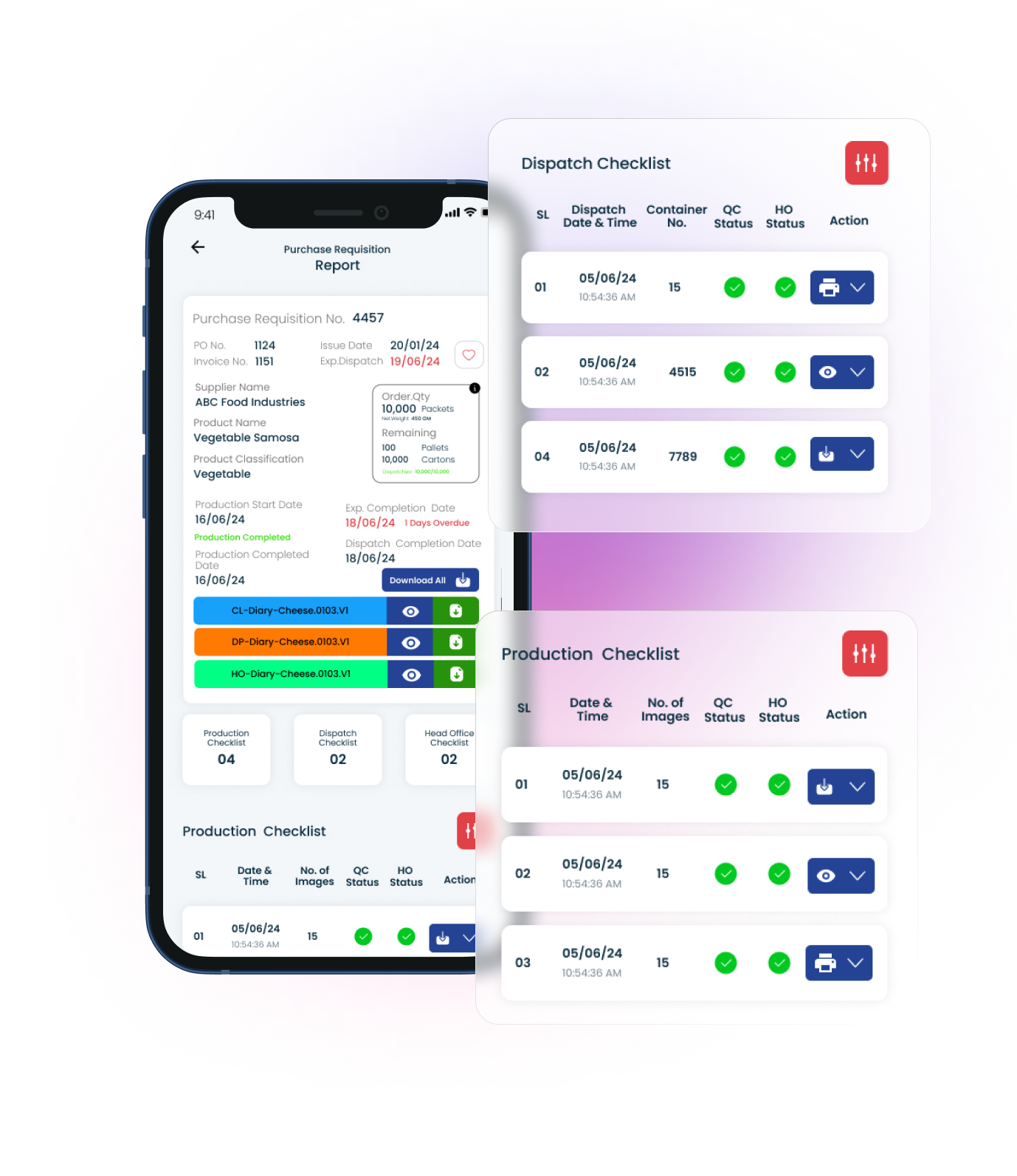

Auto-generate detailed reports.

-

Merge checklists into one view.

-

View approval/rejection analytics.

-

Export clean, printable reports.

-

Filter by inspection or supplier.

-

Visualize everything in real time.

-

Get inspection status at a glance.

-

Drill down into detailed insights.

-

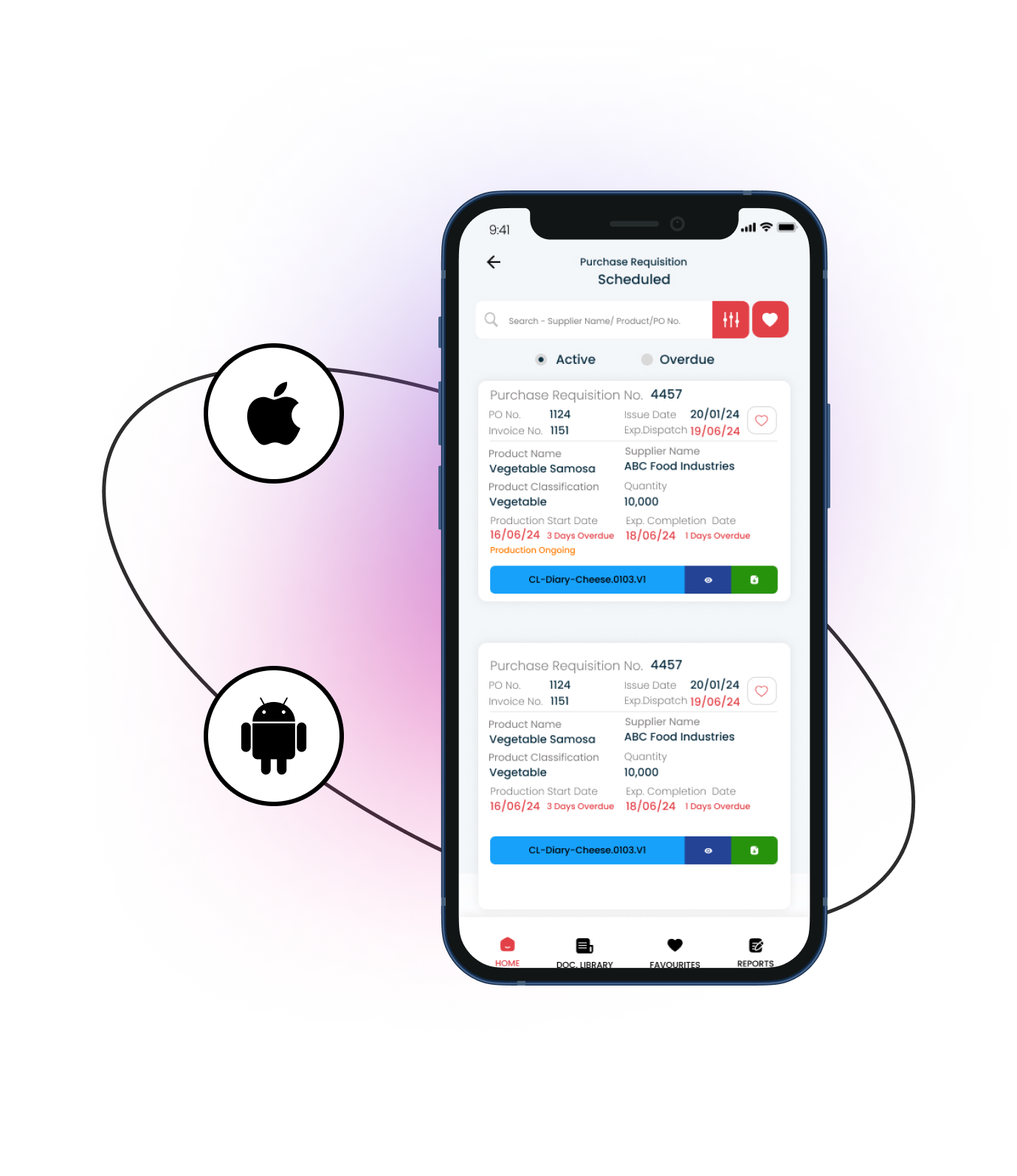

Available on iOS & Android.

-

Role-based access for users.

-

Clean, intuitive interface for fast inspections.

-

Create and control all checklists.

-

Manage users, workflows, and roles .

-

Oversee your entire inspection operation from one place.

Features

Use Cases

Awards and Achievements

Swift Check has been proudly selected by Microsoft for its prestigious Startup Founder’s Hub Program. This recognition places Swift Check among the top innovative startups chosen from thousands worldwide. The selection highlights our commitment to driving AI based digital transformation in the food industry quality management.

Swift Check helps companies achieve world-leading food safety standards such as HACCP, IFS, and ISO. By meeting the requirements of top certifications, it proves itself as a reliable digital platform for quality control. Swift Check simplifies inspections, strengthens traceability, reduces risk, and ensures full compliance.

Applications

1. Template Creation

Swift Check is an AI-driven quality and compliance management platform that helps organizations streamline supplier evaluations, inspection processes, and documentation workflows. By enabling structured template creation and automation across different modules, Swift Check ensures consistency, traceability, and operational efficiency throughout the product lifecycle.

Supplier Quality evaluation document template creation across the modules enables users to efficiently generate, reuse, and manage structured documents and checklists tailored to different stages of product lifecycle and inspection processes.

In the Product Specification Document module, users can quickly build new documents using a template builder, or clone and modify existing documents, thereby saving significant time and effort. These templates can be customized as needed and, once drafted, submitted for approval. Upon approval, the document becomes accessible to all users through a centralized library, always displaying the latest version while maintaining version history for reference or reuse.

In the Inspection Checklist module, templates can be created for each product type and reused across multiple inspections. These templates support features like image attachment, non-conformity marking directly on images, and easy checklist completion via the mobile app. The system also allows inspectors to refer to product specifications directly from the checklist.

In the Dispatch Checklist module, users can create templates that include dispatch-specific details such as container numbers and batch data. These templates support bulk photo uploads and packaging count automation based on primary, secondary, and tertiary packaging units.

In the Non-Conformity module, templates can be created to document non-conformities, including details like product name, batch number, and non-conformity type. These templates can be linked to inspection checklists and product specifications, ensuring comprehensive documentation and traceability.

2. Report Generation

Swift Check delivers powerful report generation capabilities that enhance visibility, accountability, and efficiency throughout the quality management workflow. Reports are designed to provide structured, audit-ready outputs that support faster decision-making and smoother compliance across teams and departments.

In the Inspection Checklist module, Swift Check auto-generates detailed inspection reports for each inspection, including checklist responses, compliance to product specifications, approval status, and images with non-conformity markings. Users can download individual reports or consolidate multiple inspections into a single file as a comprehensive report for broader analysis.

In the Dispatch Checklist module, Swift Check generates reports that include critical logistics and dispatch details such as container numbers, batch identifiers, packaging quantities, and bulk uploaded dispatch photos. These reports offer full traceability of outbound shipments and ensure that quality verification steps at dispatch are well documented. All generated reports from Swift Check are mobile-optimized, exportable in PDF or Excel formats, and ready for printing making them ideal for audits, compliance checks, or internal review.

The Destination Checklist module, enhances inspection processes by enabling effortless logging of container and batch information, automatic calculation of delivery quantities, and attachment of multiple delivery images. It supports destination-specific checklist templates and facilitates seamless workflows including copying, editing, approving, versioning, and instant assignment of delivery inspections. The module is mobile-friendly, supports offline inspections with one-tap submission, and incorporates built-in signature and timestamp features.

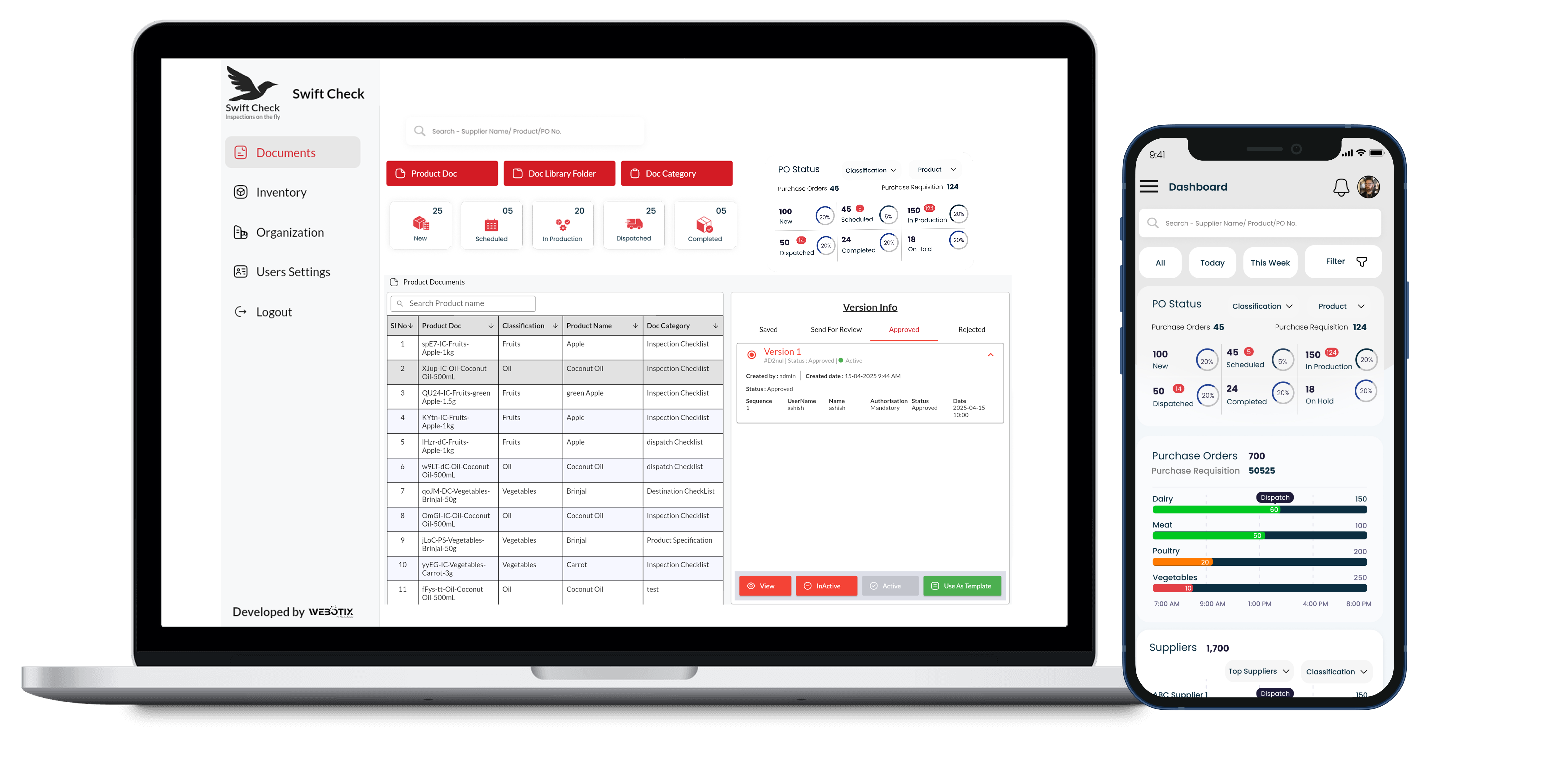

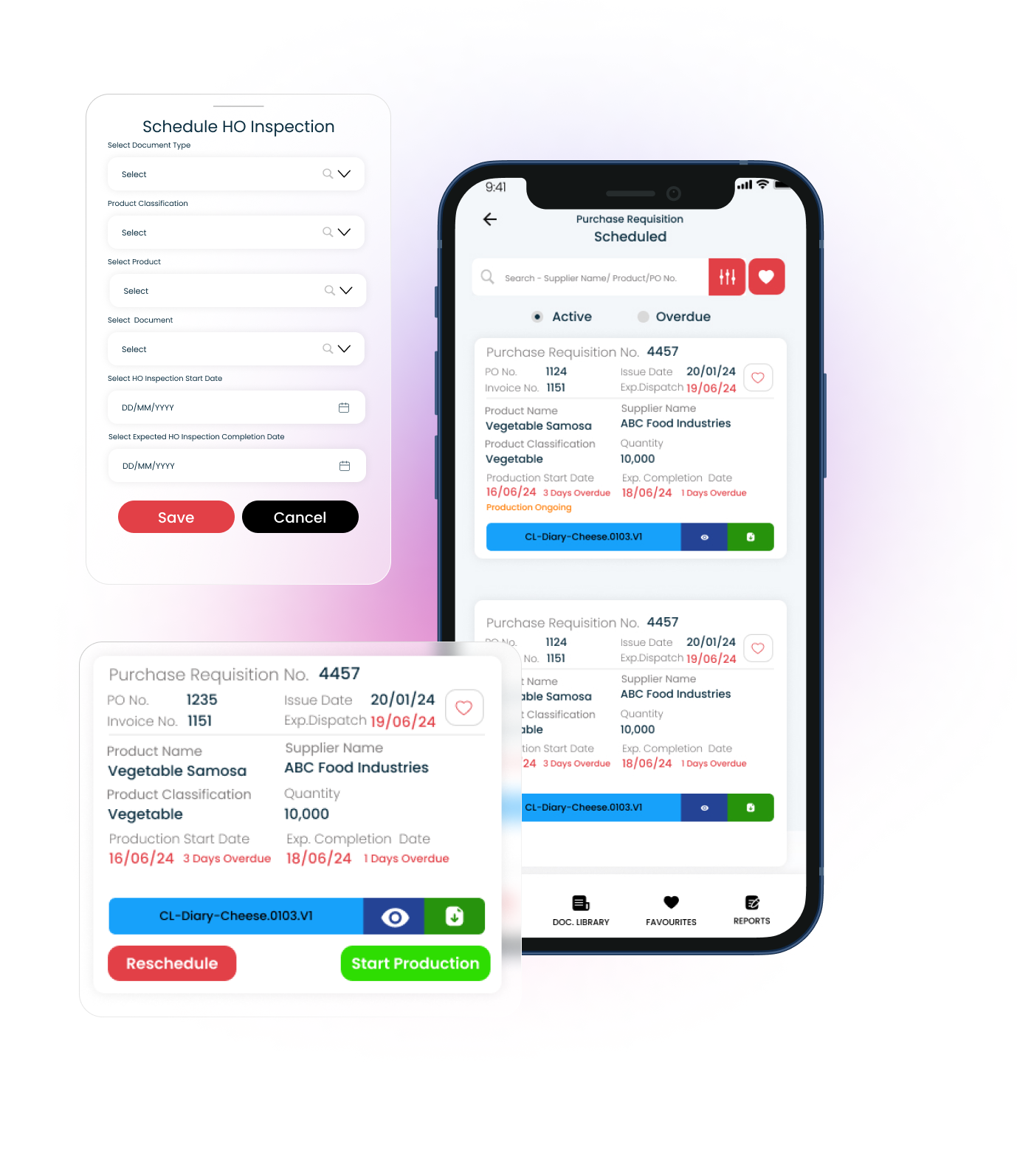

Learn More3. Scheduling and Workflow

Swift Check offers a streamlined inspection scheduling system that empowers users to plan inspections proactively for each production batch. By allowing users to assign specific checklists to corresponding products and set inspection dates, the platform ensures that inspections are conducted on time, avoiding last-minute delays or missed quality checks. This planned approach helps maintain a consistent inspection cadence throughout the production and dispatch process.

With the Swift Check mobile app, users can execute scheduled inspections efficiently in real time. Inspectors can complete checklists on the go, attach relevant images, and highlight non-conformities directly from the inspection site. This mobile accessibility not only speeds up the inspection process but also ensures that documentation is captured instantly and accurately, reducing the chances of errors or overlooked issues.

Each inspection in Swift Check follows a structured workflow from scheduling and checklist assignment to execution, review, and final approval or rejection. This systematic process ensures traceability, enforces accountability, and supports adherence to organizational quality standards. By integrating scheduling, mobile access, and a well-defined approval hierarchy, Swift Check brings consistency, clarity, and control to quality management operations.

Learn More

4. Integration with 3rd Party Apps

In today’s dynamic manufacturing landscape, third-party system integration plays a crucial role in ensuring operational fluidity and data consistency. Swift Check addresses this need by offering powerful integration capabilities that connect seamlessly with ERP systems, inventory platforms, supplier portals, and other enterprise tools. These integrations eliminate data silos and enable automatic syncing of inspection records, order updates, and supplier details across systems, minimizing manual intervention and reducing errors.

By enabling real-time data exchange, Swift Check ensures that quality control processes are always aligned with other business functions. For instance, inspection outcomes can be directly linked to procurement or production decisions within ERP systems, while supplier performance data can flow into vendor management portals for centralized oversight. This tight synchronization helps teams respond faster to quality issues, streamline workflows, and make data-driven decisions based on the most up-to-date information.

What sets Swift Check apart is its flexibility and adaptability in integrating with various third-party tools, regardless of system complexity. Organizations can customize integration touchpoints to suit their specific operational needs, whether for syncing suppliers levels, SKU’s, Invoices, and Purchase orders from existing ERP ,Legacy systems, or inventory System. This makes Swift Check a scalable and future-ready solution, empowering manufacturers to optimize quality management while maintaining interoperability with their broader digital ecosystem.

Learn More

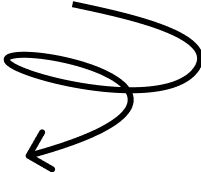

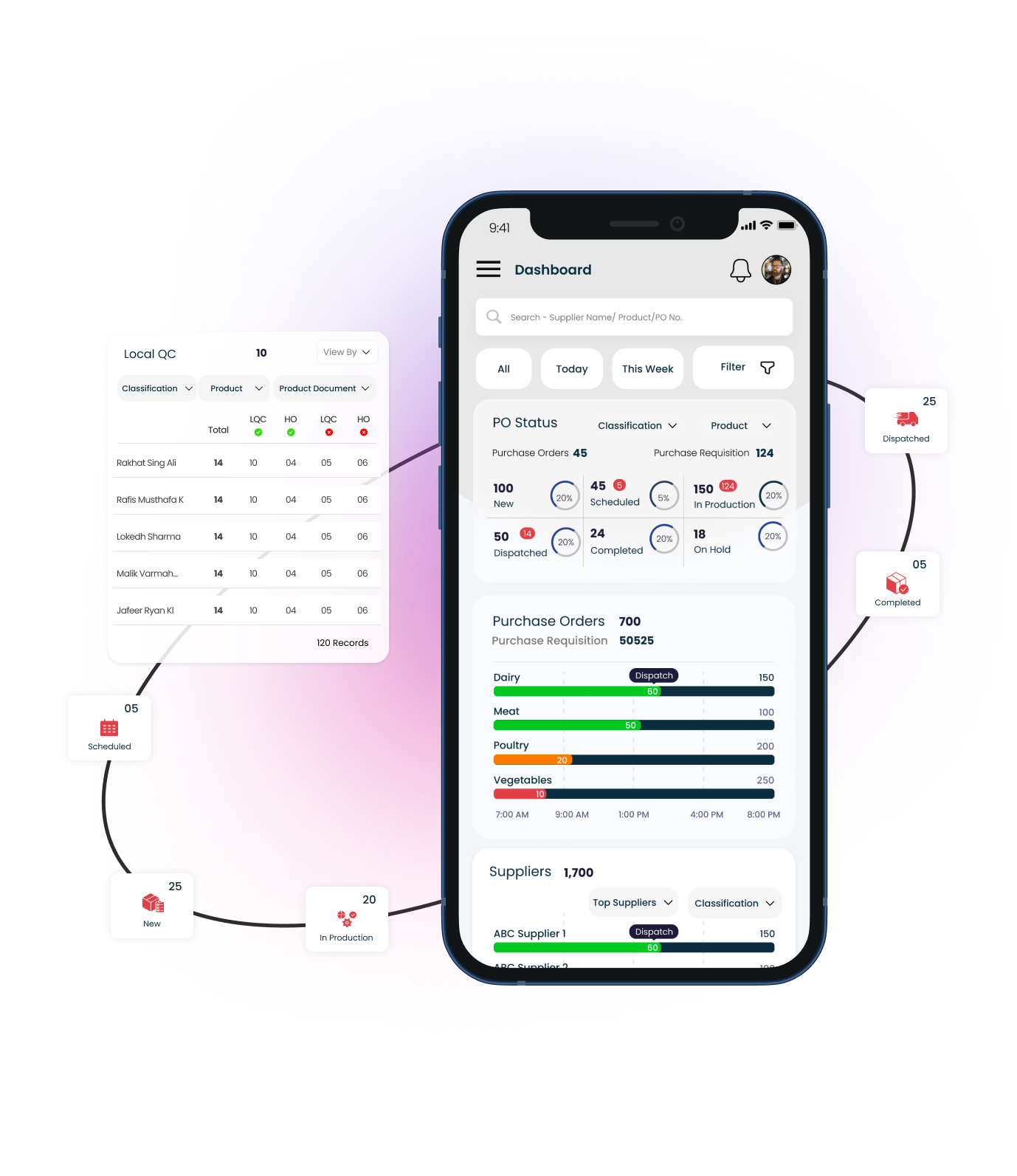

5. Dashboard for Management

The Swift Check dashboard is purpose-built to offer a centralized, real-time view of inspection and procurement activities across the organization. It consolidates critical data into a visual, easy-to-navigate interface that allows users to monitor ongoing inspections, requisitions, and approvals without switching between modules. This real-time visibility supports proactive decision-making and immediate action when delays or issues are detected.

Beyond operational tracking, the dashboard also provides deep insights into supplier performance. It displays metrics such as on-time delivery rates, quality compliance history, and inspection pass/fail trends. Users can filter this data based on user permissions. Users will get a real time insight and drilldown option to narrow the data of suppliers, product category, purchase order, purchase requisition helping teams assess consistency, dispatch identify weak links, and drive continuous quality improvement across the supply chain.

A dedicated section of the dashboard is designed to highlight top-performing suppliers, quality inspectors showcasing those who consistently meet or exceed inspection standards. This enables quality control teams and purchase officers to prioritize reliable vendors and build stronger supplier relationships. With its intelligent, role-based access, the Swift Check dashboard ensures that every stakeholder from local inspectors to senior managers has the insights they need to maintain high product quality and operational efficiency.

Learn More

Advantages

Faq

Swift Check is a digital platform that helps companies manage and streamline their supplier inspections. It replaces manual, paper-based inspection methods with smart, mobile-enabled workflows to ensure accuracy, speed, and real-time visibility.

Any business that needs to perform quality checks whether in manufacturing, food processing, garments, packaging, or logistics can benefit from Swift Check. It’s suitable for teams involved in procurement, production, quality assurance, and supplier management.

- Eliminates paperwork and manual errors

- Helps detect supplier quality issues early

- Speeds up inspections and approvals

- Ensures regulatory compliance

- Enables collaboration across departments

- Provides real-time data and reports

Traditional methods involve clipboards, spreadsheets, and delayed reporting. Swift Check replaces all of this with a centralized digital platform mobile-ready, real-time, and audit-friendly.

Yes. Swift Check can be tailored to quality-specific standards like HACCP, GMP, ISO, GFSI, and FSSAI.

Absolutely. Swift Check offers a mobile app that works on both Android and iOS. Your inspectors can complete checklists, capture photos, and log results in real time.

Yes. You can generate instant reports, track non-conformities, and review inspection results in one click. It also supports dashboards for live progress monitoring.

Yes. You can create and manage standardized checklists, version-controlled documents, and approval workflows to ensure every team follows the same quality process.

All inspections are logged digitally with timestamps, images, approvals, and remarks. You can easily access this history during internal reviews or external audits saving time and reducing risk.

Implementation is quick and flexible. Depending on the complexity of your workflows, most companies can go live in just a few weeks with the support of our onboarding team.